Project information

- Category: Engineering

- Client: Utramagic América

- Project date: 01 Sep, 2021

- Link See the project here

Design of the inventory control procedure to reduce pre-production times by searching for material in the layers area for the company Ultramagic America

Ultramagic had a problem in the control of materials necessary for production caused by the low presence of suppliers for aeronautical manufacturing in the area, This had generated a considerable delay in pre-production times.

The project had the objective of design a standardized procedure, in accordance with the ISO10013:2001 and NOM-145/1-SCT3-2001, for the control of materials applied in the area of baskets, taking into account the application of lean manufacturing tools, among which the 5S and FIFO and a program for control the inventory using Visual Basic programming and Excel platform.

Goals:

- Creating of Key Performance Indicators

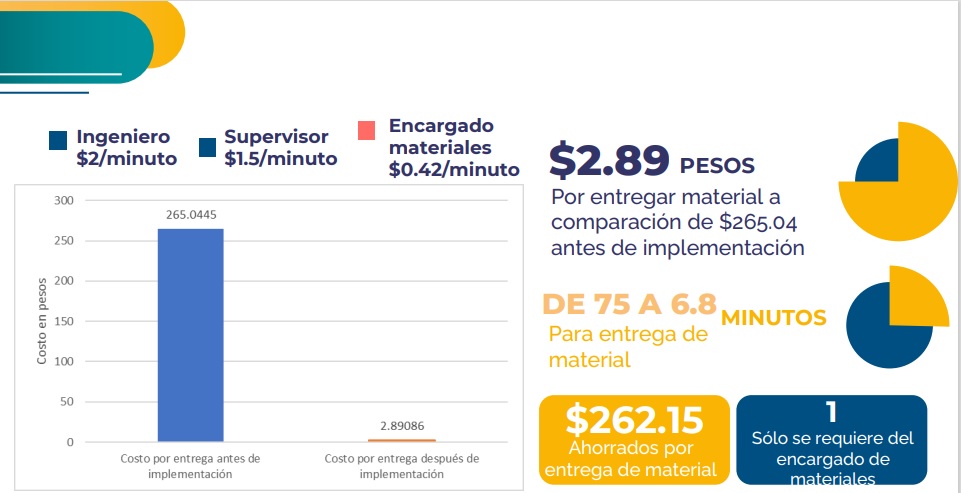

- Reduction of lead time given by the material delivery from 75 to 6.8 minutes

- Reduction of variability of inventory from 490% to 6.23%

- A fully functional system for locally control the inventory

- Standardized procedure for management of the warehouse based on ISO standars